For manufacturing companies, one of the main requirements for an order is its manufacturability. Unfortunately, in practice, we have to face a situation when the received order is not technological. This leads to an increase in the complexity of its manufacture, and, consequently, to an increase in cost. A similar situation can occur both in…

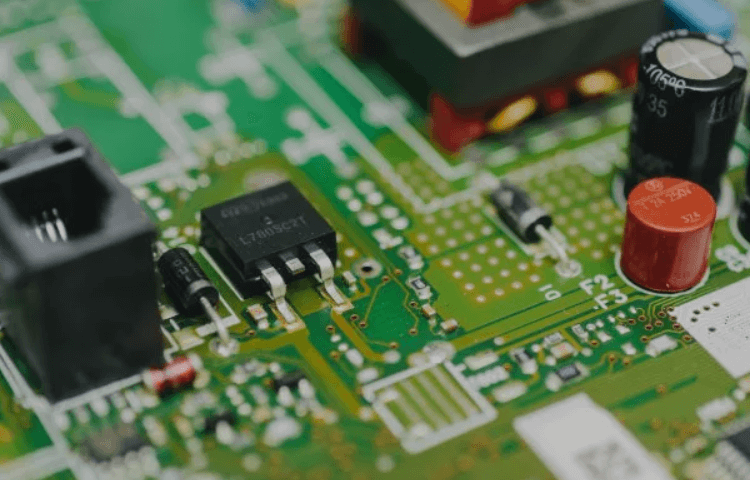

PCBs are a fundamental part of the design process in the electronic industry, and this article will provide you with an overview of what they are and how they differ from other types of circuit boards. PCBs can be utilized for prototyping, fabrication, and manufacturing purposes, but understanding all these pcb manufacturing process is important…

PCBs are used in a wide range of electronic devices, including computers, smartphones, and other digital equipment. They have become ubiquitous because they offer high reliability at a low cost. However, there are many different ways to treat the surface of a PCB before it is assembled with other components into an electronic device. Which…

Many customers due to the lack of understanding of the PCB lamination pressing process, have suffered a lot of losses: get the multi-layer board but found warping, stratification is obvious, and even the existence of serious quality problems such as the open circuit of the inner layer. The main reason is that some factories do…

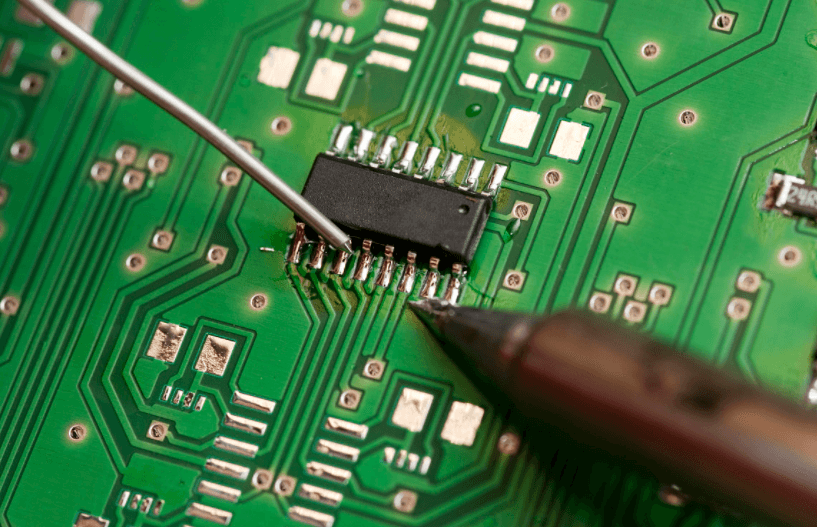

General PCB production will do the full inspection after the completion of two steps: one is the completion of the circuit (inner layer and outer layer); The second is after the finished product. The way to check the circuit after the inner and outer layer The electrical measurement method is one of the stress testing…

You’ve been hearing about Chinese printed circuit boards (PCBs) for years, but you’re not sure which China pcb manufacturer is the best choice for you.As an electronics manufacturer, you have a variety of options when it comes to the China pcb manufacture of electronic equipment. A good printed circuit board is one of the main…

Something You Need to Know About PCB Electrical Tests Why Start PCB Electrical Testing During PCB Fabrication In the production process of PCB board, it is hard to avoid electrical defects such as short circuits, open circuits, and leakage caused by external factors. In addition, PCB continues to evolve to high density, fine spacing, and…

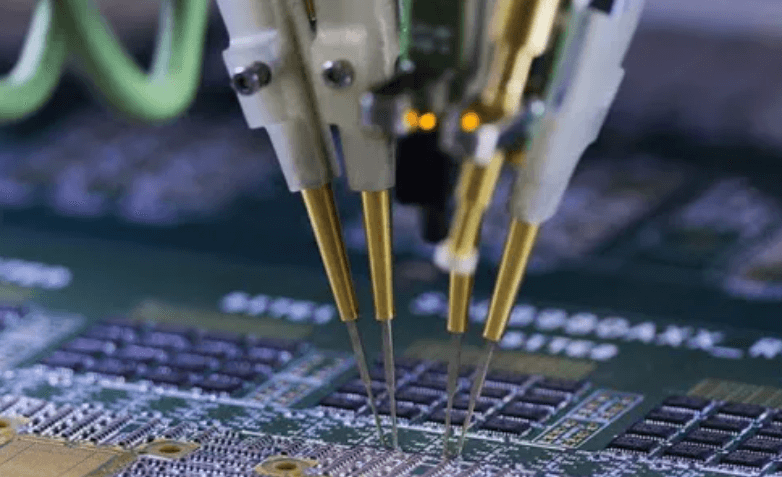

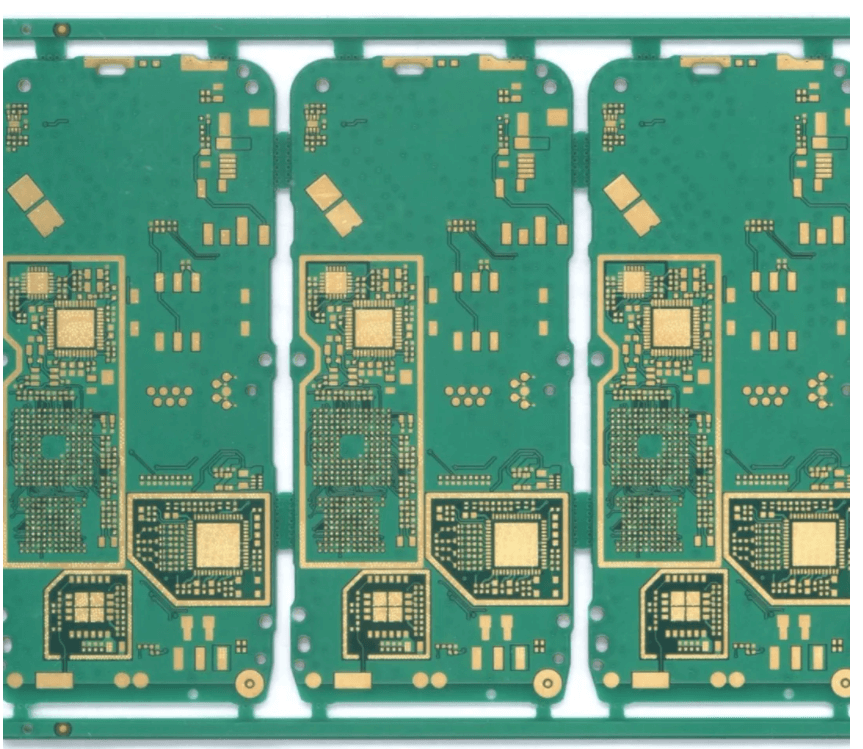

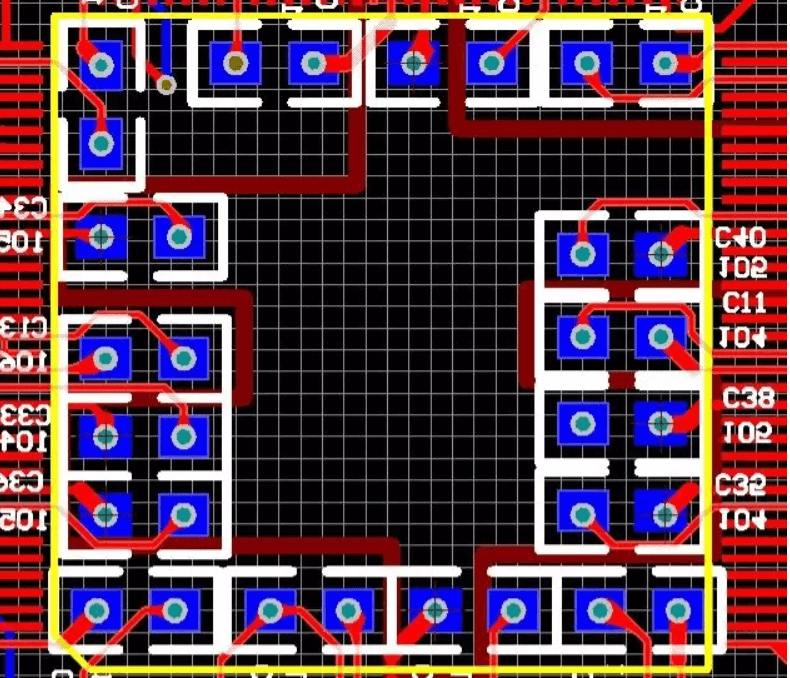

To improve PCBA production efficiency, reduce production costs, usually the PCB circuit boards will be panelized for board assembly production, which can facilitate the PCBA soldering, but also save time. The purpose of the PCB Panelization? Improve the efficiency of SMT assembly. The more the number of boards contained in a panel, the less the…

Faster Turnkey PCB Assembly Turnarounds is more than a marketing gimmick for a small PCB prototyping company intent on serving some of the most recognizable and respected technology brands on the planet. It is also a promise from the manufacturer to the customer. Turnkey PCB assembly is never a very simple operation. Faster Turnkey PCB…

Something You Need to Know About PCB Vias A circuit board is made up of layers of copper foil. The different layers of the circuit are connected by a hole (VIA). The purpose of the circuit board is to conduct electricity, so it is called a through hole. Types of PCB vias Plating Through Hole…